|

|

|

|

|

. |

|

ET 200

|

ET 220

|

ET 210

|

ET 103 |

|

ET 220 -

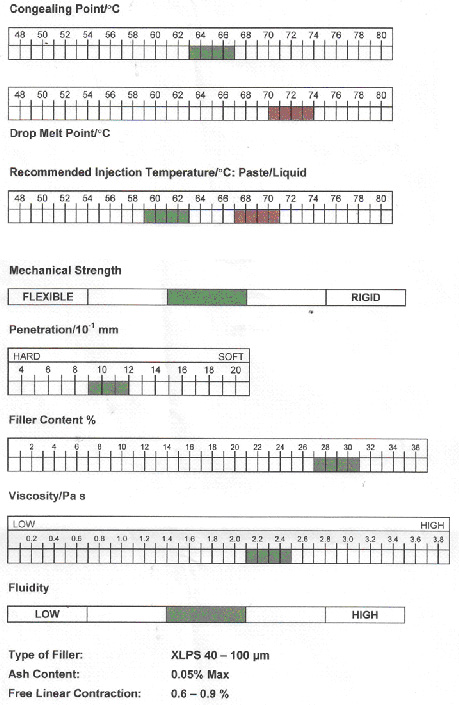

FILLED PATTERN WAX : |

PHOTO GALLERY |

|

• A

Pattern Wax specifically for the production of commercial type

castings

• A medium viscosity , Filled , pattern Wax

• Quick setting wax with minimal cavitations / sink age

• Dimensionally very stable

• Can be used as a liquid injection material but performs better

if injected at or below the recorded congealing point

• Capable of producing patterns of all sizes , and thick or thin

sections

• Non-sticky requiring very little release agent for removal

from dies

• Returns to shape if distortion occurs on removal from the die

• The wax can be reclaimed fro runner systems.

|

|

|

Recommended maximum melting temperature of 100 C, While

maintaining the wax at temperatures exceeding 68 C it should be

stirred slowly and continuously to prevent any filler from

separating. When the wax is in the injection machine tank we

suggest that if the holding temperature is lower then 66 c no

stirring is necessary, between 66- -68 C stir occasionally. |

|

|

|

|

TYPICAL PROPERTIES : |

|

|

|

|